CENCERA THERMAL SYSTEM BASED ON MATERIAL, ENERGY, AI AND MECHANICS

CENCERA THERMAL SYSTEM BASED ON MATERIAL, ENERGY, AI AND MECHANICS

基于材料,能量,人工智能,和机械的中硅热工系统

Heat treatment facilities

Facilities for the perovskite, glass, steel sheet, aluminum sheet, copper base metals industry and fiber industry.

Our heat treatment facilities feature the following advantages:

Multi choices: thermal float furnace, multichambered furnace, medium hardening, maglev, etc.

High quality: highest throughput, long service life, lowest environmental impact

State-of-the-art process and artificial intelligence

Cost-effective operation: low anneal costs, high availability, low maintenance requirements, best price/performance ratio

Excellent anneal results: homogenous microstructure, cleanest material surface, no material loss, uniform mechanical properties

CENCERA’s pioneering concepts in modern burner technology create new perspectives in offering environmentally friendly and energy efficient solutions.

热处理系统

用于玻璃,钙钛矿,钢铁,铝材,铜材,以及纤维行业的设备

CENCERA热处理系统具备以下特点:

多技术融合:热工,气浮,媒介淬火,等等

质量可靠、高产能、使用寿命长、环境危害低

先进的热处理工艺及人工智能控制

高效的生产:运行成本低、高可用性、低维修、最佳的性价比

极佳的产品:均匀的微观组织结构、清洁的材料表面、无材料损耗、一致的机械性能

CENCERA在烧嘴工艺方面创新性的理念提出了环保节能化解决方案的新观点。

Turnkey Solutions for thermal forming sheet:

- Process consultation

- Steel sheet

- Aluminum sheet

- WHEEL including rim and disc

- CARTRIGE, TRAY for power battery

- GLASS including windshield, backlite, and roof

板材热成形的整线解决方案:

- 工艺顾问

- 超高强度钢热成形

- 铝合金热成形

- 轮毂热成形,包括轮辐和轮辋

- 动力电池盒,托盘,

- 玻璃,如前挡风,天窗,后挡风

Thermal float furnace vs. Roller hearth glass tempering furnace:

- Up to 250% higher performance

- Up to 50% less energy consumption

- Higher availability 30% less maintenance & higher OEE

- Ultra thin glass tempering with superior quality

超薄玻璃钢化采用热浮炉比较于传统辊道式玻璃钢化炉:

- 达到 250% 更高的性能

- 达到 50% 的节能

- 更高的可靠性, 减少30%的维修, 更高的OEE (Overall Equipment Effectiveness)

- 超薄玻璃的钢化有更好的品质

Tailored Tempering Properties (TTP) for hot-forming steel products: door rings, power battery trays, floor panels, wheel hubs, vehicle axles, etc.

- Soft zones around the perimeter, with a hard central area.

- Solves welding crack issues (traditional connections use CO2 shielded welding).

- Increases lifespan.

- Directly replaces existing traditional aluminum alloy products.

- Achieves higher load-bearing capacity for vehicles.

- Enhances safety redundancy and protective structures.

- Low-stress structure, reduces maximum dynamic principal strain, improves fatigue resistance, and enhances fatigue strength.

- Improves vibration and noise reduction, lowers vehicle noise, and attenuates vehicle vibration.

- Compared to traditional cold-worked steel, it reduces weight, decreases electricity consumption, and cuts down on carbon dioxide emissions in the environment.

热成形钢的分区强化(TTP)技术用于多个领域:双门环,动力电池托盘,大地板,轮毂,车桥,等等

周边软区(Soft zone),中间硬区(Hard zone)

解决焊接开裂 (传统连接用CO2保护焊)

寿命延长

对现有传统铝合金制品直接替换

实现车辆更高承载能力

提高安全冗余保护结构

低应力结构,最大动态主应变降低,提高抗疲劳强度

减振降噪效果,降低车辆噪声,衰减车辆振动

相较传统冷作钢,减少质量,减少电耗,减少二氧化碳的排放量

Roller-hearth furnaces (single layer, or multi layers)

Roller-hearth furnaces (single layer, or multi layers)

The roller-hearth furnace for heating glass, perovskite, aluminum, and fibre blanks offers impressive productivity at low investment costs and features rugged, straightforward construction with easy access for maintenance.

Technical data:

nominal width: 1,000-4,500 mm

heated length: 8 ~ 160 m, tailor made

heating:

- gas radiant tube heated

- gas radiant tube-heated + electric heating elements (HYBRID)

- electric radiant tube-heated + electric heating elements

辊底炉,单层或多层

辊底炉适用于玻璃,钙钛矿,钢板, 铝合金,以及纤维材料毛坯的热成形处理,以较少的投资成本实现可观的生产率,其特点在于结构简单坚固,便于检修

技术数据:

有效加热宽度: 1,000 ~ 4,500毫米

有效加热段长度: 8 ~ 160米

加热方式:

- 燃气辐射管加热

- 辐射管式燃气加热 + 电加热元件 (混合式加热)

- 辐射管式电加热 + 电加热元件

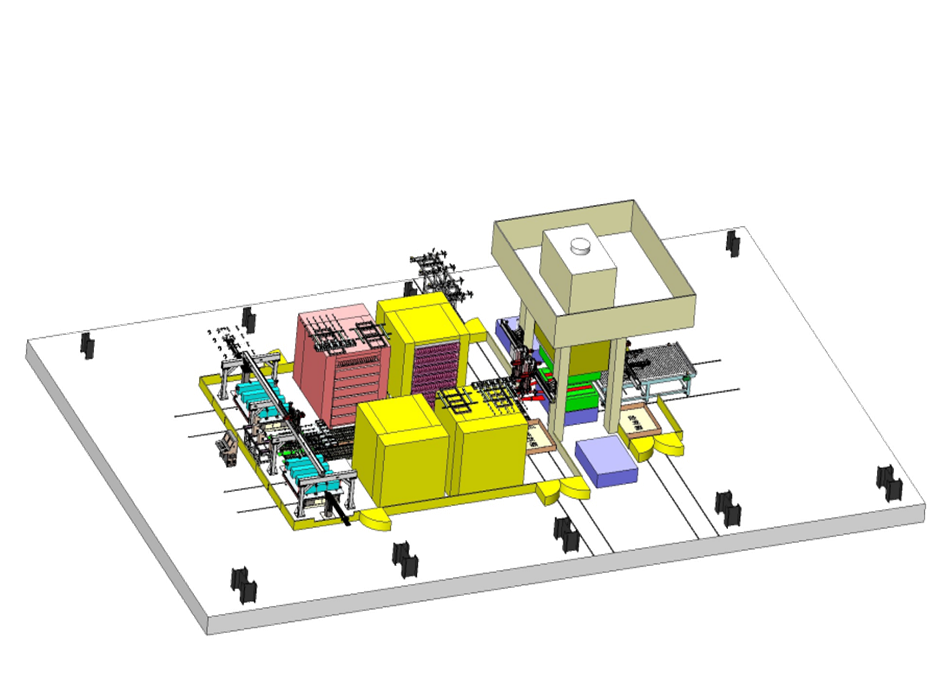

Multi-Chamber batch-type furnaces

The multi-level batch-type furnace for heating perovskite, glass, steel alloy such as 22MnB5, aluminum, fibre blanks is especially designed to optimize space requirements. Strong blank supports without hearth rollers enable galvanized blanks to also be processed. The chamber furnace is used for testing of new tools before delivery in mould factory, new methods in hot stamping plant and research organizations, new materials in steel works. This kind of furnaces can make short production series, customer demonstrations, and prototype manufacturing. Multilayer feeder furnace can have one to twenty two chambers.

Technical data:

Nominal width: 4,500 mm. The length of the workpiece can be up to 4,200mm.

Heated length: 3,500 mm. The width of the workpiece can be up to 3,250mm.

The maximum thickness of the sheet can be up to 25mm.

The maximum weight of the workpiece can be up to 100kg.

Heating:

Gas radiant tube-heated + electric heating elements (HYBRID)

Electric radiant tube-heated + electric heating elements

Induct heating

多层厢式炉

多层厢式炉适用于玻璃,钙钛矿,钢板, 铝合金,纤维材料坯料的热处理,专为优化空间结构设计。不带炉辊且坚固的料片支撑,使得镀锌板也可以加工。

技术数据:

有效加热宽度: 3,500 毫米

有效加热段长度: 3,500毫米

加热方式:

辐射管式燃气加热 + 电加热元件 (混合式加热)

辐射管式电加热+电加热元件

感应加热

Improved process stability and availability

Meets the CQI-9 Standard

Compact solution

Precision heating

Easy maintenance

Handles different material combinations / coatings

改进的工艺稳定性和易用性

满足CQI-9标准

紧凑的解决方案

精准控温加热

容易维护

加工处理不同材料/涂层

The characteristics of CENCERA atomization and spray system:

Air blast atomization

Medium blast atomization

Nozzle against thermal shock and distortion, zero thermal expansion under 1,260°C

CENCERA雾化与喷淋系统的特点:

空气助力喷射雾化

媒介(包括水)的喷射雾化

喷嘴零膨胀, 不变形,不堵塞,具备强抗热冲击性能

UNIQUE Design, atomization, spray, and quenching

CE-PURE 陶瓷布气管,雾化系统, 钢化风栅

Artificial Intelligent Thermal System (AI Thermal)

The performance is orientated by edge computing based on big data.

From day one, CENCERA has equipped its heat treatment facilities with high-quality control systems produced in-house. That is why we have considerable experience in power engineering, electronics, data processing and process control systems. Self developed edge computing module optimizes product process parameters with the accumulation of production data.

The CENCERA-developed AI Thermal range includes complete power distribution systems and control centers plus process control systems, visualization systems, software, mathematical models and documentation.

人工智能系统

性能以基于大数据的边缘计算为导向。

CENCERA的热处理设备配备本厂生产的优质的控制系统。CENCERA在热能工程、电子工程、数据处理以及过程控制系统方面具有丰富的经验。自研边缘计算模块,随生产数据的累计,最优化产品工艺参数。

CENCERA研发的人工智能热工系统包括完整的能量分配系统、控制中心、过程控制系统、可视化系统、相关软件、数学模型以及文档。

Transfer feeder Fork system

- The fork doesn’t deform under high temperature.

- Hi rigid. Vibration with less amplitude, low frequency whilst moving at high velocity.

- 20% higher acceleration

- 20% lower weight

- 10% lower energy consumption

料叉快速进出料系统

- 温升后料叉不变形翘曲

- 高刚度。高倍速时振幅小,频率低。

- 20% 提高加速度

- 20% 减轻重量

- 10% 减少能耗

BUSINESS SCOPE:

🏅 CENCERA Thermal Materials and Systems

💯 Zero-expansion high-temperature structural ceramics (Dust-free material. Shape block, crucible, tray, roller, tube, mold with precision 3D contours and profiles. Monolithic block with max. dimensions of height 2,000mm, length 8,000mm and width 3000mm)

💯 Multi-layer chamber furnaces: Perovskite crystal annealing, steel and aluminum hot stamping, heat treatment, glass forming

💯 Air circulation furnaces: Solution annealing, aging of alloy

💯 Thermal float furnaces (air cushion furnaces, air float furnaces): Ultra-thin glass tempering, ultra-thin aluminum sheet/strip, copper strips/belts, titanium alloy strips heat treatment

💯 Roller hearth furnaces: Single layer or multi-layer. Perovskite crystal annealing, steel and aluminum hot stamping, heat treatment, glass tempering, press forming

💯 Intelligent production management systems, remote control monitoring systems, centralized control systems, after-sales equipment monitoring service platforms

💯 Key components for thermal systems: FTIR Spectrometer, fan, motor, heating elements, burners, thermal imagers, temperature measurement devices, insulation materials, atomizer, nozzle, sprinkler, etc.

💯 Technical services: Process consulting and training, simulation, CQI-9 Thermal System Assessment Process Certification

经营范围

🏅️ CENCERA 中硅热工材料及系统

💯零胀耐高温结构陶瓷 (无尘。型砖,坩埚,辊棒,多曲面模具。单一陶瓷件最高2,000mm, 最长8,000mm, 最宽3,000mm)

💯多层厢式炉:钙钛矿结晶退火,钢铝热冲压,热处理,玻璃成形

💯空气循环炉:固溶,时效,

💯热浮炉(气垫炉, 气浮炉):超薄玻璃钢化,超薄铝板带,铜板带,钛合金板带热处理

💯辊道炉:钙钛矿结晶退火,钢铝热冲压,热处理,玻璃钢化,压制成形

💯介质淬火/钢化系统:风栅钢化,多孔板钢化,水淬,介质淬火。分区淬火。分区回火。

💯智能生产管理系统,远程控制监视系统,集控系统,售后设备监控服务平台

💯热工系统关键零部件:风机,电机,燃烧器,电热丝,辐射反射板,单/双色计,红外测温,光谱仪, 热电偶,保温材料,气氛元件,雾化器,喷淋头,等等

💯技术服务:仿真,工艺咨询和培训,CQI-9热系统评审过程证书

CENCERA CORPORATION

Add.: Rm 710, Bldg. 3, Nb. 116, Chengyang Rd., Suzhou 215131 China

Factory: 50 Hongqi Rd., Haining, Zhejiang 314419 China

HP: 0086 – 13918089208

Http://www.cencera.com/

Email: cencera@hotmail.com

Contact: Mr. Charles Chen

Skype: bizsci@hotmail.com

苏州中硅装备科技有限公司

浙江中硅新材料有限公司

地址:苏州市相城区澄阳路116号大数据产业园3号楼710室215131

电话:13157375999

Http://www.cencera.com/

电子邮件:cencera@qq.com